What Is Supply Chain Management

Managing supply chains includes overseeing the entire production journey from raw materials to finished products, and is vital in manufacturing and retail, impacting customer satisfaction, cost control, and financial efficiency through streamlined operations and timely deliveries.

How Supply Chain Management Works?

Supply chains includes various elements vital to their efficient functioning:

Enhanced efficiency in sales and operations

Efficiently managing supply chains employ diverse strategies to optimise overall operations, streamlining the flow of products, materials, and information. It bolsters business efficiency through precision demand analysis and sales forecasting.

Consequently, understanding what is supply chain management investing in SCM results in the punctual delivery of finished goods or services, contributing to heightened customer satisfaction.

Furthermore, SCM facilitates seamless information exchange, fostering business growth.

Cost reduction

Organisations increasingly recognise the value of effectively managing supply chains in trimming costs. Through real-time data analysis, it minimises purchasing and production expenses.

The supply chain vigilantly monitors financial inflows and outflows, ensuring the smooth economic operation of businesses.

Acknowledging why is supply chain management important allows organisations to oversee operations, control costs, and allocate resources efficiently and meticulously.

Risk evaluation and mitigation

Anticipating and evaluating risks in advance equips companies to navigate disruptions adeptly. Managing supply chains uses predictive analysis, offering end-to-end visibility to detect and mitigate issues.

By recognizing how supply chain management works, businesses can proactively take corrective measures, enhancing flexibility, precision, and efficiency across various processes like product development and demand and supply planning. It optimises value-chain nodes, positively impacting business outcomes.

Elevated customer experience

Effectively managing supply chains plays a pivotal role in managing and executing tasks to elevate customer experiences.

It prioritises customer needs, responding to them in real time and ensuring on-time delivery. Prioritising customer preferences fosters retention and solidifies a company’s reputation.

Furthermore, an interconnected network of suppliers and distributors expedites the accurate delivery of products and services to customers.

Improved collaborative relationships

Nurturing synergistic and profitable relationships through effective communication is a fundamental benefit of efficiently managing supply chains.

In volatile market conditions, businesses should share information in real time, fostering a growth-oriented environment with suppliers and vendors.

Thus, maintaining productive relationships is crucial for cost control and ensuring long-term business sustainability.

Quality assurance

Efficiently managing supply chains ensures demanding quality control. It monitors critical tasks, including timely delivery, final product quality, supplier quality assessments, compliance checks, and more.

Maintaining product and service quality is essential for delivering a superior customer experience. Managing supply chains enables businesses to adhere to government standards and guidelines, ensuring prompt detection and resolution of quality control issues.

Minimised delays

A smoothly functioning supply chain leads to fewer logistical errors and enhances the consistency of distribution processes. Managing supply chains provides real-time data to minimise delays in delivering goods and services to customers.

Reduced delays are a massive advantage of managing supply chains, particularly in maintaining business agility and resilience. Effective coordination and collaboration optimise shipping processes.

Demand-supply management

Profound insights into the supply chain ecosystem empower organisations to predict and manage demand effectively. Crafting innovative strategies is imperative to respond to evolving market trends.

Comprehensive oversight of supply chains enables businesses to exhibit agility and responsiveness.

Technology adoption

Modern technological trends augment the capabilities of supply chain management. Automation tools enhance overall operational management, offering businesses a competitive edge.

Implementing cutting-edge technology optimises processes and offers a competitive advantage, fortifying the functionality of managing supply chains and enabling business expansion.

Business agility

Managing supply chains imparts resilience and adaptability to businesses, allowing them to seize opportunities.

Forward-thinking companies prioritise efficient logistics processes to align with changing market trends, delivering enhanced customer value.

Supply chain agility accommodates actual and unforeseen demand fluctuations, leveraging technologies like the Internet of Things, Big Data, and Artificial Intelligence in Logistics.

Strategies for Supply Chain Optimisation

Lean supply chain management

The notion of “Lean” has a long history, primarily within manufacturing, as a team-driven method for ongoing enhancement. Its core objective is the removal of activities that don’t add value from the customer’s perspective.

Recently, this approach has found application in managing supply chains and logistics management.

Benefits of lean supply chain management:

Improving employee morale: The successful adoption of a lean management approach empowers employees, significantly boosting their morale. Content and motivated employees tend to yield better results, creating a positive work environment.

Waste reduction: Implementing a lean strategy helps eliminate waste across all functions and sectors, reducing bottlenecks and positively impacting lead times within your organisation.

Lowering inventory costs and ensuring product availability: Lean practices enable reductions in finished stock, work-in-progress items, and raw materials, resulting in overall inventory cost reductions.

Agile supply chain strategies

Employing the following agile supply chain strategies is vital for responsive method of managing supply chains:

Adaptability

An agile supply chain possesses the ability to promptly respond to changes, uncertainties, and customer demands. For instance, if your peach supplier runs out, an agile approach ensures your business keeps running smoothly, even during unforeseen challenges.

Comprehensive oversight

In agile supply chain management, control translates to a comprehensive view of the entire supply chain process. It’s akin to having a bird’s-eye perspective from sourcing raw materials (like peaches) to delivering customers’ final product (milkshakes). This control minimises risks, enhances reliability, and fosters effective collaboration among supply chain partners.

Timely and precise information

Accurate information includes real-time data on inventory levels, customer preferences, market dynamics, and supplier capabilities. With this information, informed decisions can be made, demand fluctuations predicted, and production and delivery plans adjusted swiftly. It reduces the likelihood of errors, streamlines operations, and better aligns with customer needs.

Quick decision-making

Fast decision-making is essential in the face of unexpected disruptions. It may involve empowering employees to make decisions based on their insights. Effective communication and collaboration within the supply chain network enable rapid information sharing and joint problem-solving.

Flexibility

Supply chain flexibility allows rapid adaptation to shifting demand, market conditions, or disruptions. It includes scaling production, altering suppliers, and adjusting distribution methods as needed. It ensures efficient response to customer needs and a competitive edge in dynamic markets.

Innovation

Embracing innovation involves continually seeking new ideas, technologies, and approaches to enhance processes, products, and services. Whether devising novel methods to create peach milkshakes or improving their resistance to melting on hot days, innovation keeps you ahead of the competition and attuned to evolving customer needs.

Sustainability

Sustainability includes considering the supply chain’s environmental, social, and ethical impact. It comprises waste reduction, carbon emission reduction, responsible sourcing, and fair treatment of workers.

Integrating sustainability ensures compliance and enhances your brand’s appeal, attracts environmentally conscious customers, and creates lasting value for all stakeholders.

Demand forecasting and planning

Demand forecasting involves predicting customer preferences for existing products or services and deciding how to adjust production or introduce new offerings. Yet, predicting people’s desires in terms of quantity and timing is a complex task.

It can range from specific timelines like “Should we increase chip production on Fridays versus Thursdays?” to broader periods like “Over the next month” or “Throughout the coming year.”

When applied to a specific product a company offers, demand forecasting yields the same outcomes as a sales forecast. However, it takes on a more generalised approach in other scenarios, often at the product-category level.

Consider questions like “How many electric SUVs will be in demand in 2023?” or, more broadly, “What’s the expected demand for electric vehicles?”

Demand forecasters use various techniques, selecting the most suitable method based on the specific case or scope.

Why Is Demand Forecasting Important for Businesses?

Demand forecasting is crucial for businesses, as even reasonably accurate predictions offer valuable insights, allowing for informed decisions on cost-cutting, production expansion, or maintaining the status quo.

While effective inventory management depends on these forecasts, preventing customer dissatisfaction, revenue loss, and excessive expenses, making it especially vital for growing small and midsize enterprises to avoid inaccurate scaling and potential cash drain.

Supply Chain Technologies and Tools

Role of technology in supply chain optimisation

- Competitive advantage via technology: Staying ahead is crucial in today’s fiercely competitive market. Effective deployment of advanced technology is vital. Consider:

- Artificial Intelligence and Machine Learning enable automated processes and end-to-end supply chain optimisation.

- Internet of Things (IoT): IoT devices enhance visibility and reduce costs.

- Cloud solutions: Cloud-based tools improve data integration, security, and information sharing.

- Autonomous mobile robots (AMR): AMR optimises the picking process.

- Blockchain: This technology enhances traceability and security in the supply chain.

- Enhanced customer satisfaction: Leading global supply chains aim to eliminate operational bottlenecks and streamline procedures to improve customer satisfaction. Technological innovation accelerates businesses, boosts ROI, and leads to happier customers.

Inventory management software

Inventory management software allows organisations to track, manage, and optimise inventory levels efficiently. It helps prevent overstocking, stockouts, and reduces carrying costs. Advanced features often include demand forecasting and order automation. Inventory management also helps in ensuring product availability and maintaining stable flow of raw materials for manufacturing or production.

Supply chain analytics and big data

Big data in the supply chain encompasses vast volumes of structured and unstructured data generated by various supply chain processes, including social media sentiment, weather information, and text-based documents. It revolves around data’s volume, variety, and velocity.

On the other hand, supply chain analytics systematically analyses data throughout the supply chain, from procurement to distribution, with goals like better decision-making, increased operational efficiency, cost reduction, and overall performance improvement.

Supplier Relationship Management (SRM)

Supplier Relationship Management (SRM) is a strategic approach used by organisations to manage and improve their interactions with suppliers. It involves fostering strong, mutually beneficial relationships with suppliers to enhance managing supply chains efficiently and achieve common goals.

Some key aspects of SRM include:

Cultivating strong supplier partnerships

SRM extends beyond operational concerns to ethical and sustainable considerations:

- Responsible sourcing: Conscientiously selecting suppliers that adhere to ethical labour practices, environmentally responsible manufacturing, and social responsibility.

- Environmental consciousness: Incorporating environmental considerations into supplier selection, emphasising sustainable sourcing decisions to minimise ecological impact.

- Social responsibility: Ensuring suppliers uphold ethical labour standards, respect human rights throughout the supply chain, and maintain safe working conditions.

- Promoting sustainable supply chains: Contributing to developing supply chains that prioritise sustainability and social responsibility, aligning with global environmental and ethical standards.

Risk mitigation in supplier relationships

SRM plays a crucial role in identifying and mitigating risks associated with supplier interactions:

- Risk preparedness: Proactively reducing the likelihood of disruptions by focusing not only on optimising operations under normal circumstances but also on days when things deviate from the norm.

- Diverse risk forms: Recognising that supplier risks manifest in various forms, such as miscommunication, errors, price hikes, and termination of supplier relationships.

- Risk mitigation strategies: Anticipating and mitigating risks through vigilant monitoring, open communication, and collaboration, enabling timely responses.

- Bargaining leverage: Equipping organisations with greater bargaining power to address challenges, explore alternative suppliers, and maintain diversified supply chains to minimise risks.

Ethical sourcing and sustainability practices

SRM extends beyond operational concerns to ethical and sustainable considerations:

- Responsible sourcing: Conscientiously selecting suppliers that adhere to ethical labour practices, environmentally responsible manufacturing, and social responsibility.

- Environmental consciousness: Incorporating environmental considerations into supplier selection, emphasising sustainable sourcing decisions to minimise ecological impact.

- Social responsibility: Ensuring suppliers uphold ethical labour standards, respect human rights throughout the supply chain, and maintain safe working conditions.

- Promoting sustainable supply chains: Contributing to developing supply chains prioritising sustainability and social responsibility, aligning with global environmental and ethical standards.

Supply Chain Resilience and Risk Management

Supply chain resilience and risk management is a strategic approach that ensures a supply chain can withstand disruptions, adapt to changes, and maintain essential functions. It involves identifying, assessing, and mitigating potential risks from natural disasters, geopolitical factors, and supplier issues, allowing for quick recovery and minimal impact on product or service delivery.

Identifying and managing supply chains risks

Identification process

- Supplier instability: Vendor bankruptcy necessitates swift replacement, often posing considerable challenges, especially for complex products.

- Supply chain disruption: External factors like natural disasters or political turmoil can halt supply chains. Suppliers relying on others for raw materials amplify the impact.

- Compliance and regulatory breaches: Supply chain operations are subject to numerous laws and agreements covering corruption, labour, and human trafficking. Violations can lead to severe penalties and legal action.

- Reputation damage: Unethical behaviour by suppliers within your supply chain can tarnish your business’s reputation. Discovering supplier involvement in child labour, unsafe working conditions, or other legal breaches can have far-reaching consequences.

Management process

Step 1: Risk identification

Begin by mapping and evaluating the value chains of major products in your supply chain. Scrutinise each node, including suppliers, plants, warehouses, and transport routes. Document all identified risks and areas requiring further investigation.

Step 2: Establish a risk management framework

Score each risk in the register using a consistent methodology based on three factors:

- Impact on the organisation if the risk occurs.

- The likelihood of it happening.

- The organisation’s readiness to address it.

Apply tolerance thresholds aligned with the organisation’s risk appetite. This framework allows for prioritisation and identifies high-risk products and value-chain nodes.

Step 3: Continuous monitoring

Implement persistent monitoring using digital tools to track leading indicators of risk. Customise monitoring systems to your organisation’s needs, considering impact, likelihood, and preparedness perspectives. Early warning systems are crucial for tracking top risks and enhancing mitigation efforts.

Step 4: Building robust defences

Strong defences are essential for identifying and preventing unknown risks before they disrupt operations. It includes incorporating risk considerations in request-for-proposal language and providing comprehensive worker training.

Strategies for Supply Chain Resilience

Diversify inventory locations

Put all your inventory in a different place. Distribute it across multiple locations to reduce the risk of disruptions caused by factors like equipment failures or extreme weather events. Implement a robust inventory management system that enables quick access to supplies across various locations and ensures demand management.

Foster strong supplier relationships

Effective supplier communication is vital for maintaining supply chain visibility and avoiding delays. Utilise software to track supplier performance and maintain real-time data access. Building relationships with suppliers allows mutual awareness of potential shipping problems and collaborative solutions.

Collaborate with multiple suppliers

Relying on a single preferred supplier can increase vulnerability to disruptions. Diversify your supplier base by working with multiple suppliers in different regions. It minimises the impact of delays from a single source, enhancing resilience.

Expand carrier options

Similar to diversifying suppliers, use multiple carriers for shipping. Different carriers offer varying rates and policies, and having backup carriers ensures continuity in case of issues with the primary choice.

Harness the power of data

Leverage advanced data analytics tools to enhance supply chain forecasting and efficiency. Analyse data to optimise inventory management, prevent shortages, and identify overstock causes. Utilise artificial intelligence and machine learning to monitor local and global conditions for potential disruptions.

Business continuity planning

Business Continuity Planning is a strategic organisational approach aimed at guaranteeing the uninterrupted functioning of essential business operations in the event of unforeseen disruptions or disasters.

It involves the development of comprehensive plans and strategies to maintain critical operations and reduce downtime during adverse circumstances.

Business continuity planning includes the following key elements:

- Risk evaluation: BCP commences with thoroughly evaluating potential risks and threats that could disrupt regular business operations. It includes the identification of natural disasters, technological breakdowns, supply chain interruptions, security breaches, and other conceivable risks.

- Business impact analysis: Organisations scrutinise the possible repercussions of each identified risk on critical business functions. This analysis aids in prioritising tasks that are most crucial and demand immediate attention during a crisis.

- Formulation of continuity plans: Organisations devise comprehensive continuity plans for each after pinpointing critical functions. These plans delineate strategies, protocols, and required resources to ensure the continuous operation of these functions during a crisis.

- Resource allocation: Adequate resources, including personnel, equipment, and facilities, are assigned to support the execution of continuity plans. Backup systems and data recovery solutions may also be put in place.

- Testing and training: Continuity plans undergo periodic testing through simulations or drills to ascertain their effectiveness. Employees receive training to comprehend their roles in times of crisis and how to implement the strategies.

Measuring Supply Chain Performance

Measuring the performance of a supply chain involves evaluating various insights into different facets of the supply chain.

Some common methods for measuring supply chain performance are as follows:

Key performance indicators (KPIs) in supply chain management

KPIs are specific metrics and indicators that measure supply chain performance, such as cost efficiency, delivery reliability, inventory management, and customer satisfaction.

Common KPIs include:

- On-time delivery rate.

- Inventory turnover.

- Order fulfilment cycle time.

- Supply chain cost-to-revenue ratio.

- Customer fill rate.

Continuous improvement and six sigma in supply chains

Continuous improvement is an ongoing process of enhancing supply chain performance by identifying and eliminating inefficiencies and defects. Six Sigma is a structured methodology aimed at reducing process variation and imperfections.

Together, they help optimise supply chain operations by focusing on data-driven decision-making, process standardisation, and defect reduction.

Benchmarking for success

Benchmarking involves comparing an organisation’s supply chain performance against industry peers or best-in-class organisations to identify areas for improvement. Companies can set performance targets by analysing how top performers achieve their results and implement best practices to enhance their supply chain operations.

Conclusion

The field of managing supply chains offers immense opportunities for those looking to start a career in supply chain management. You must have the proper knowledge and skills to excel in this dynamic industry.

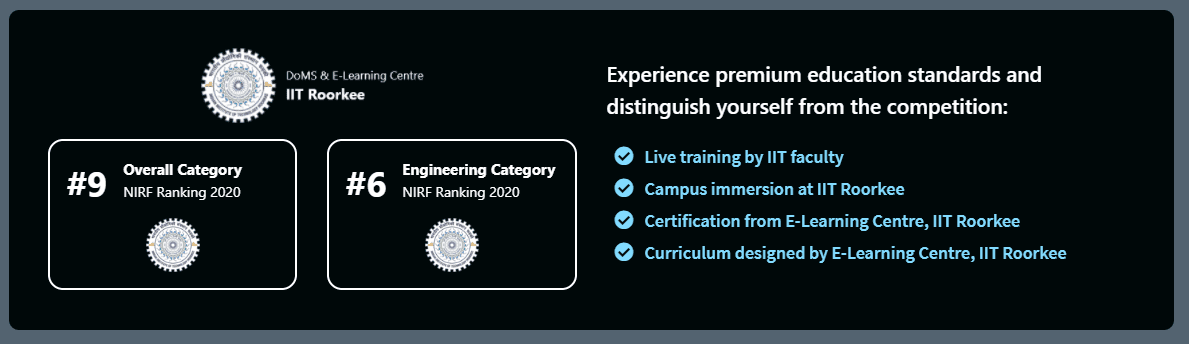

That’s where Imarticus Learning’s Advanced Certificate In Supply Chain Management And Analytics, CEC, IIT Roorkee course comes into play.

Our supply chain management courses provide a comprehensive grasp of why is supply chain management important in today’s business, supply chain operations and analytics, catering to both professionals and beginners seeking to excel or start their career in supply chain management.

Visit Imarticus Learning today to learn more about our supply chain course.

Other than being a top course endorsed by an IIT, this allows the aspirants to become better at decision making. It also permits an in-campus interaction with other students and faculty.

Other than being a top course endorsed by an IIT, this allows the aspirants to become better at decision making. It also permits an in-campus interaction with other students and faculty.