Supply chain management is a very crucial concept to sustain any business in today's world. The fundamentals of supply chain management are concerned with the inflow and outflow of goods, services, data, finances and anything related to a product or service. A proper flow within the supply chain is very important which starts right from the procurement of raw materials and continues till the delivery of the finished goods at its destination.

Supply chain management (SCM) is a centralised concept where various departments come together to manage the flow of goods and services within the supply chain. Knowing how to forecast demand and coordinate the planning of the supply chain is an integral part of supply chain management. One can learn these essentials by taking an efficient supply chain management course to get a better understanding.

Read on to learn demand forecasting, planning and its importance in supply chain management. Planning the various processes of the supply chain and coordinating the dynamic activities are some essential skills that one needs to master to become a successful supply chain professional.

What is Demand Forecasting?

Recognising the essence of demand forecasting and its essential functions in preparing a company's logistic initiative is a major step in understanding the concept of demand forecasting in supply chain management. Supply chain managers take a cyclical approach to forecasting demand by gathering and analysing historical data and performing market analysis with the help of sophisticated data models.

Accurate demand forecasting is a very important step in supply chain management as it involves inventory management, scheduling of manufacturing and production and making data-driven strategic business decisions, based on predictions. Professionals need to tactically balance consumer needs and cost-effectiveness throughout the SCM process. Demand forecasting helps to enhance a company's market position and increase the profitability of the business.

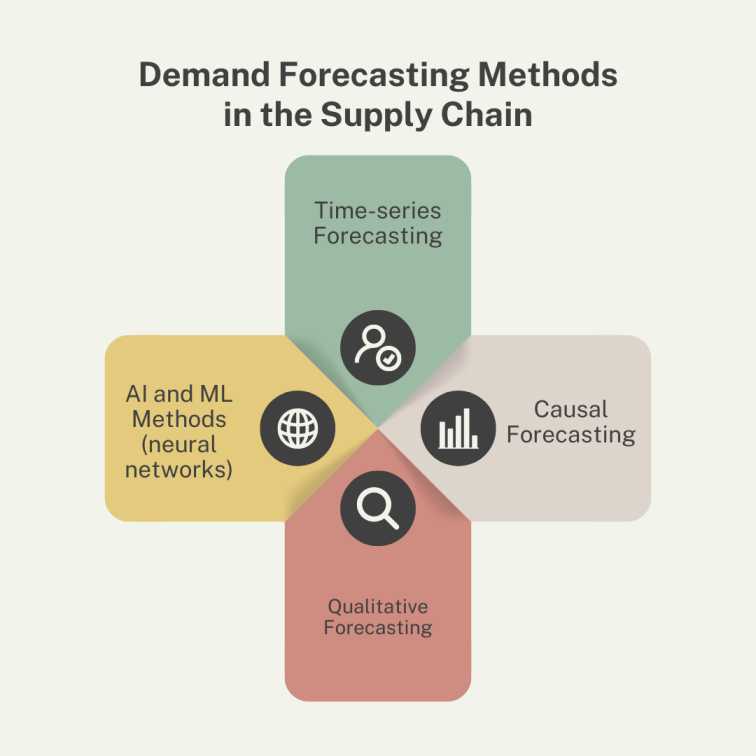

Demand Forecasting Methods in the Supply Chain

There are various types of demand forecasting in supply chain management but all of them have the same foundation which is data. All the demand forecasting methods are based on the availability of data such as historical sales data, predictive data, valuable insights for making action plans, etc. Hence, it is clear that the available data creates a direct impact on the quality accuracy and utility of demand forecasting activities.

The following are the various types of demand forecasting methods used in the process of supply chain management:

Time-series Forecasting

This demand forecasting method relies upon past performance and historical data to make predictions regarding future demand. This is done by analysing the past patterns of sales, demand, production and manufacture of the product. 'History repeats itself' is the cardinal principle of this method.

However, this method of demand forecasting tends to eliminate the possibility of any major change that may affect the demand for a particular product. Many important external factors are overlooked in this method such as the competitors' next moves, market fluctuations, inflation etc.

Time-series forecasting is a great choice in case of a stable market condition with reliable and consistent demand. It is a cost-effective method that produces straightforward results.

Causal Forecasting

The method of causal forecasting is based on a cause-and-effect relationship between multiple variables. These variables are extremely important and create a great impact on the economic indicators that are essential for making forecasts about the future demand for a product. Supply chain managers extend marketing efforts and build strategies on the basis of demand forecasting.

However, critics consider the method of causal forecasting a very complex one but it is well-known for its accuracy in predictions. It can be used to make wise business decisions but requires skilled personnel for making forecasts.

Qualitative Forecasting

The qualitative approach of forecasting is used when the historical data for that particular product is missing. This method largely depends upon market research, new industry trends and professional judgment. Predictive intuition plays a great role in this method as there is no support for historical data.

Critics may disregard qualitative forecasting because of its subjective nature but it is crucial in circumstances where there is a dearth in actual data. The effectiveness of this method heavily depends upon the amount of industry knowledge, experience and expertise of supply chain professionals.

AI and ML Methods (neural networks)

The new-age approach of AI and ML methods uses neural networks to enhance the accuracy of demand forecasting. These techniques use the power of machine learning and enhance the predictive accuracy of new products. This method can easily get a hang of complicated and non-linear relationships that can be used to get accustomed to new data.

However, experts regard this method to be very complicated and resource intensive but the major advantage that this method offers is the ability to deal with large quantities of data in a convenient manner. It can positively identify hidden patterns which makes it a great innovation in the world of demand forecasting.

Best Practices in Demand Forecasting

Businesses need to conform to several best practices while performing demand forecasting in order to enhance the accuracy levels in predictions and to completely utilise its benefits. The following are the best practices in demand forecasting:

Use high-quality data

While predicting the future demand for certain products, it is important that supply chain managers use data-driven techniques. Such data should be reliable and consistent.

Using high-quality data is one of the major reasons for performing successful demand forecasting. The data needs to be cleaned and authenticated from time to time to increase the prediction accuracy. Additionally, supply chain managers should be trained enough to understand the hidden patterns and insights of certain data.

Select a suitable forecasting method

Select an appropriate forecasting method based on the characteristics of the business, the range of the goods and services, the market trends and customer demand patterns. Also consider factors like cost effectiveness, market volatility, seasonality and demand trends while choosing the demand forecasting approach that best satisfies the business's unique requirements.

Collaborate across departments

To build an effective supply chain, a business needs to properly collaborate across various departments such as sales, marketing, operations, finance and so on. For this, proper communication channels should be maintained so that it becomes easier to extract data, analyse insights and understand the meaning of hidden patterns.

Dynamic business strategies should be decided upon and aligned to ensure effective collaboration across various organisational departments. Departmental collaboration increases accuracy in forecasts and enhances the decision-making system in the organisation.

Understand demand drivers

Supply chain professionals need to gain a deep understanding of the various demand drivers that affect the demand for certain products in the market. Demand drivers are those factors that influence the market demand for a product. It is important to locate major market factors, consumer behaviour, competitor's actions and economic indicators in the industry.

In order to improve the accuracy and depth of demand forecasting, professionals can incorporate their knowledge and expertise in demand forecasting models to improve the entire process of supply chain management.

Consistently review and update forecasts

Demand patterns can take a shift and transform as they do not remain constant for a longer period. Hence, it becomes crucial to regularly scrutinize and review the forecasts. Also, asking for feedback from the management and incorporating certain changes can enhance the forecasts.

Supply chain professionals need to supervise and analyse the market trends, customer behaviour, industry dynamics and various other external factors to make sure that the forecast remains relevant and precise.

Coordinating Activities of Supply Chain Management

Managing the supply chain is much more than just calculating inventory and recording logistics. Supply chain managers perform diverse functions to keep costs down which results in the enhanced efficiency of the supply chain process of the organisation.

Good supply chain managers coordinate various activities that are known as the pillars of supply chain management. If you want to learn how to coordinate supply chain activities in an efficient manner, consider taking a supply chain course.

In supply chain management, the manager has to coordinate multiple logistic activities that mainly consist of the following parts:

Planning

The process of supply chain management starts with the planning stage where supply chain managers align supply with the customer trends and manufacturing demands. Demand planning helps them to achieve the best results and also anticipate future demands in order to take appropriate action. Planning involves collecting raw materials that are required in every stage of manufacturing, assessing the abilities and competitiveness of each instrument and noting the labour requirements for carrying out the entire process.

Generally, large organisations frequently use Enterprise Resource Planning (ERP) systems to gather data and generate action plans accordingly.

Sourcing

Sourcing is one of the main pillars in the SCM process where businesses need to maintain good and cordial relationships with the suppliers. Sourcing employees gathering and using raw materials that are essential for the entire manufacturing process. professionals work closely with the vendors to arrange raw materials at the right time and in appropriate quantities.

Companies may draw manufacturing plans in advance so that they can secure raw materials from the supplier without any delay. However, different industrial sectors have different sourcing requirements. Some of the major sourcing requirements are enumerated as follows:

- The supplied raw materials comply with the specifications that are required in the manufacturing process for the production of goods.

- The cost of the raw materials and the finished goods are in alignment with the market standards.

- The supplier has the liberty to send emergency supplies in case of unavoidable circumstances.

- The reputation of the supplier should be such that they deliver good quality materials on time.

Supply chain management can get extremely critical when concerned with perishable goods. When sourcing raw materials, businesses should take care of the lead time and how conveniently a supplier can comply with the necessary standards.

Manufacturing

Manufacturing is that part of supply chain management where workers convert the raw materials into finished goods with the help of labour, capital, machinery and various other external sources. Procuring good quality finished goods is the main aim of supply chain management.

The manufacturing process can further be divided into various subcategories such as assembling testing packaging and inspecting the finished goods. Businesses should take care of the costs involved in making the final products and also the generation of waste. These elements should not divert from the original SCM plan. If any diversion from the original plan takes place then such issues must be rectified at the earliest.

Delivering

After the manufacture of the products they are sold in the market and once the sales are finalised the products need to be delivered to the customers. The customer interaction with the product has not yet taken place and delivering the products to the customer is seen as the first step of interaction between the brand and the consumers. Hence, the delivery process must be seamless and customers should not face any sort of difficulties or else it will lower the brand image.

In a seamless supply chain management process, companies generally build high-performing delivery channels for safe and timely delivery. To ensure delivery essentials they do not completely rely on any one method of delivery rather they make provisions for multiple delivery methods. These methods ensure the safety of the products and are also cost-effective.

Returning

The process of supply chain is not yet complete. Sometimes there can be products that a customer purchases but does not like or it comes with some sort of issues. In such cases, consumers place return requests for the product. So, accepting a return request and adjusting the product cost is also a part of the process of supply chain management.

It is already bad for the brand if a customer needs to return a product but it can get even worse if the return request is not processed hassle-free. Companies must be able to take return items and process the refunds for such items. It is also known as reverse logistics. This is where the supply chain management process concludes.

Methods of Planning Supply

Supply planning is the practice of aligning and coordinating various tasks associated with the production and distribution of finished goods and services in order to fulfil consumer demand. Supply planning is the way to ensure that the business has the potential to deliver what the customer wants at the right time.

Supply planning consists of various methods. For someone interested in building a career in supply chain management, getting a good understanding of supply planning is a crucial part. Some of the most frequently used methods are enumerated as follows:

Demand forecasting

The first thing to ensure proper supply is to predict the demand for a particular product. Demand forecasting is the way of knowing what the demand for a product could be and how the customers will react to it. There are various means of forecasting demand that are generally data-driven in nature. Supply chain managers need to analyse the data and make forecasts about the future demand for a product in order to proceed with supply planning.

Inventory review

Inventory review is the approach of stocking products in the warehouse after knowing the already existing stock that is kept in the warehouse. According to smart supply chain managers, one needs to store only the amount that is to be supplied to the consumers. Hence, there is no point in producing and storing enormous amounts of products in the warehouse.

Supply chain professionals need to properly analyse the current inventory levels in the warehouse and produce only the required amount of products that have been estimated in demand forecasts.

Sourcing and procurement

After assessing the inventory report, supply chain managers get a clear understanding of what products they need to stock, what they have in abundance and where they may fall short. To stock the required inventory in the warehouse, sourcing and procurement are absolutely essential.

Retailers choose reliable suppliers to acquire products as and when required. The suppliers provide the retailers with an adequate amount of raw materials and other essential items that are necessary for making the finished goods. Such is the process of sourcing and procurement which is an integral part of supply planning.

Distribution planning

Distribution planning is the process of dividing the inventory in the proper places. Storing inventory at the wrong place at the wrong time is of no use. Hence, supply chain managers need to ensure that they have the right amount of inventory distributed organically in various areas. Supply chain professionals build a plan to properly distribute the inventory throughout the operation centres.

Performance monitoring

After performing all the steps in supply planning, supply chain managers need to constantly supervise the performance of their supply chain to see what gaps to fill. Professionals analyse and mark areas that need to be improved. Such areas can be anything starting from inventory tracking, planning production schedules, monitoring delivery times and so on.

However, a significant part of performance monitoring is to determine whether the suppliers are meeting their delivery commitments or not. If there exist any discrepancies, supply chain managers need to take the appropriate corrective actions to solve any performance alignment issues.

Conclusion

Businesses can build a highly successful supply chain management framework with proper demand forecasting and procurement, coordinating various activities and raising the standards of supply planning. Businesses can earn great benefits if they properly comprehend client needs and streamline the process of stocking inventory in terms of higher levels of customer satisfaction, cost savings and enhanced profitability.

For performing such activities companies need efficient supply chain professionals who understand the fundamentals of the process. If you are looking forward to building a career in supply chain management, consider signing up for the Advanced Certificate In Supply Chain Management And Analytics, CEC, IIT Roorkee by Imarticus. This supply chain analytics course will help you understand the concepts of supply chain and analytics for becoming a successful new-age supply chain professional.