After the advent of digitisation and e-commerce, the supply chain has become the backbone of most businesses. We need to have a proper supply chain mechanism in place if we want to sell through online mediums. Building a new supply chain can be a complex and challenging process. But with the right approach and tools, it is possible to create a highly efficient and effective system that meets the needs of our organization. If we focus on how to become a supply chain analyst, then it can do wonders to create an effective supply chain.

One approach that can be particularly useful in this context is macro-ops planning, which involves taking a holistic view of the supply chain and considering all of the factors that can impact its performance. But how to build an effective supply chain using macro-ops planning? How can we learn about macro-ops planning in the first place? Let’s find out!

Steps to Build a New Supply Chain Using Macro-Ops Planning

Developing a macro-ops plan is essential. We can enrol for a supply chain management course with analytics to learn macro-ops planning. Let’s save it for later. Here are some key steps to follow when building a new supply chain with macro-ops planning:

Defining The Goals and Objectives

Before we start building a new supply chain, it is important to have a clear understanding of what we hope to achieve. This might include goals such as reducing costs, improving delivery times, or increasing customer satisfaction. Defining goals sets a clear direction of where we will be heading.

Assessing The Current Supply Chain

To build a new supply chain that meets our needs, it is important to first understand the strengths and weaknesses of our current system. This might involve analyzing data on key metrics such as delivery times, costs, and customer satisfaction, as well as conducting interviews with key stakeholders to gather insights and ideas for improvement. Once we get an idea of our current systems, we know the lacunas that lie in them and craft a definite plan for improvement.

However, if it is the first time that we are developing the supply chain, then we need to have a thorough understanding of our business model. Knowing about how the supply chain functions in our industry can be of great help in creating an effective supply chain for our organisation.

Identify Key Drivers of Performance

Once we have a good understanding of our current supply chain, the next step is to identify the key drivers of performance that need to be considered in our new system. This might include factors such as demand patterns, supplier capabilities, transportation options, and inventory management practices. Changes in these drivers can be most effective in developing the new supply chain.

Develop a Macro-ops Plan

With an understanding of our goals, current systems and the key drivers of performance, we can then begin to develop a macro-ops plan for our new supply chain. This might involve creating a detailed roadmap that outlines the key steps and milestones that need to be achieved, as well as identifying the resources and capabilities that will be required to implement the plan. The macro-ops plan should be carefully curated as it will be the foundation of all our future actions and the effectiveness of our new system. We can learn to develop the macro-ops plan through the IIT Roorkee supply chain management course (discussed later).

Implement and Optimize the New Supply Chain

With our macro-ops plan in place, we can then begin the process of implementing and optimizing our new supply chain. This might involve making changes to our processes, systems, and infrastructure, as well as working closely with suppliers and other stakeholders to ensure that the new system is running smoothly. What we need to remember is that the changes won’t happen overnight. We need to continuously monitor the execution of the macro-ops plan and how the changes are delivering the results.

Developing an Effective Macro-Ops Plan

Adopting a macro-ops planning approach can help us build a new supply chain that is highly efficient and effective, and that meets the needs of our organization. However, it is important to develop an effective macro-ops plan. Further, we also need to have in-depth knowledge of supply chain systems and how they function. But how can we do so?

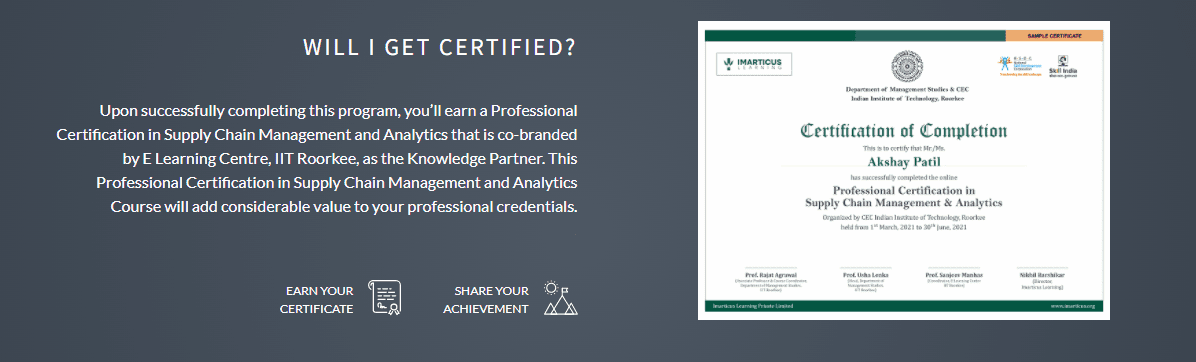

We can become supply chain analysts if we focus on learning from a supply chain management course with analytics. IIT Roorkee has designed a comprehensive course on supply chain management – Professional Certification in Supply Chain Management & Analytics that provides us with hands-on learning and deep insights into real-world SCM projects. You can access this course through Imarticus Learning. Mentoring with industry experts provides cutting-edge experience to candidates willing to enter the supply chain and operations industry.

The curriculum of the IIT Roorkee supply chain management course is carefully designed to meet the current age supply chain management needs that use the latest technologies and features. The campus immersion allows us to interact with the top industry leaders and some of the smartest minds and peers in this industry. But it’s incomplete without practical insights, right? The real-life industry projects allow us to learn from the practical projects implemented by some of the biggest MNCs across the world.

Are you ready to develop and implement your new supply chain with macro-ops planning? Get enrolled now with Imarticus Learning.

This course introduces new-age technology for the automation and optimization of supply chains to prevent bottlenecks. The institute also provides projects and organizes live sessions. These will help you develop essential skills and gain industry experience. You can choose a

This course introduces new-age technology for the automation and optimization of supply chains to prevent bottlenecks. The institute also provides projects and organizes live sessions. These will help you develop essential skills and gain industry experience. You can choose a