RPA stands for Robotic Process Automation, which is a new system used in supply chain management systems. RPA automates those processes that are otherwise operated manually. This reduces errors and anomalies drastically. It allows the companies to utilize their employees for actual brainstorming rather than correcting the various issues on a regular basis.

RPA has had a major impact on the daily operations of a supply chain system with its productivity increasing many folds in recent times. If you intend to choose a supply chain management course with analytics, having a general idea about its impact will be beneficial.

Pros and Cons of RPA in the SCM industry

It has not been long since RPA was used in SCM so it may not be time to judge it to be a good or bad move. But it has been in use for a while to see what are its advantages and drawbacks.

Benefits of RPA in SCM

- Order processing and payment

Processing the orders and tracking the payments are some of the most difficult tasks in the supply chain system. But automating both of these, companies can save time and effort while making it simple for the customers or the company to keep track. The automation includes timely processing of the orders and sending out bills through emails and text messages.

- Communications

It is important to keep track of the processes and inform the involved parties about the progress or delays concerning the shipments, etc. The automated email system sends out emails whenever an order is placed, the product is shipped, or out for delivery. Such automation makes the system transparent and reliable.

- Inventory management

Every certificate course in supply chain management teaches that this is the most important department of the supply chain. Inventory management is a major part of the supply chain and by automating this department, companies can ensure the balance of supply and demand. The automated system can send notifications for low levels of stock and reordering processes. It could also use historical data to predict the inventory levels depending on the demand.

- Shipment status

Communication of the shipment status could be completely automated right from the opening line of the email to assessing what the customer expects from such communication. Sending out the regular updates of the shipment is one such example and it will require minimal human intervention and only on some rare occasions.

- Supply and demand planning

RPA helps gather, compile, analyze, and present the data for the regular planning for supply according to the demand. By using AI and ML, reduces common human errors and makes the system more efficient.

Drawbacks of RPA in SCM

Rather than considering it as a drawback it would be better seen as a challenge that could have a solution in the near future. The common issues with RPA in SCM are

- Standardizing the processes even with proper documentation

- Need for constant IT support

- Keeping up with the expectations of stakeholders and gaining their trust to implement the RPA system

- Engaging the employees and making them accept the system

Conclusion

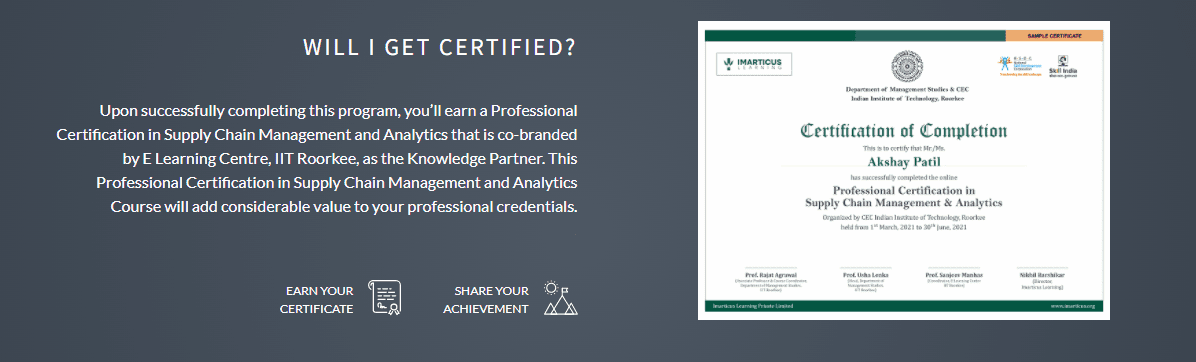

The world is moving forward with technological advancements so every industry must keep up with these changes. The SCM system requires professionals having such advanced skills and that is the reason why one should opt for the supply chain management online course such as the Professional Certification In Supply Chain Management & Analytics at Imarticus.

It will help you be a supply chain manager who has a thorough knowledge of the latest developments in this system.

Here are 7 reasons why you must consider technologizing the supply chain using advanced analytics and AI:

Here are 7 reasons why you must consider technologizing the supply chain using advanced analytics and AI: