The supply channels of the industry are experiencing a crucial moment for their existence and those responsible for this vital area for any business face the greatest challenge of their careers; manage an innumerable list of suppliers, information and communication flows, technologies, procedures, and levels of demand, as never before in the history of the global industry.

These supply networks have grown in complexity appreciably and have suffered the consequences of the global economic crisis with particular virulence. To help you understand the importance of technologizing the supply chain using advanced analytics and AI, we offer an SCM program where you can obtain a certification in supply chain management.

Here are 7 reasons why you must consider technologizing the supply chain using advanced analytics and AI:

Here are 7 reasons why you must consider technologizing the supply chain using advanced analytics and AI:

- Agility is key to success, more than ever. Designing supply chain network systems must work like a clock, and take advantage of new technologies, such as IoT, Blockchain, or Artificial Intelligence, to reach new levels of efficiency.

- Advanced analytics is another alternative high impact in this world, taking into account the permanent state of evolution and change network provision of any business. Evaluating the best options, those that provide the greatest value and margin, and taking advantage of all the data at our disposal has an immediate positive consequence on the results. Thankfully, our professional certification in supply chain management explains how advanced analytics is beneficial for the supply chain management.

- The information must be analyzed comprehensively and quickly, with the powerful support of the cloud. The large corporations are moving quickly so that their supply chains are aligned more with your customer strategy, and are connected more directly, accurately, and flexibly. But, above all, an “always ON” supply chain is sought that responds to commercial needs at all times.

- The interconnection of all its links is crucial for the machinery to function and respond to the demanding market conditions. Analyzing that information has profound implications for B2B processes. For this reason, one of the fundamental attributes of this supplier ecosystem is its “resilience”, understood as the ability to anticipate and react immediately to any potential anomaly that could endanger it.

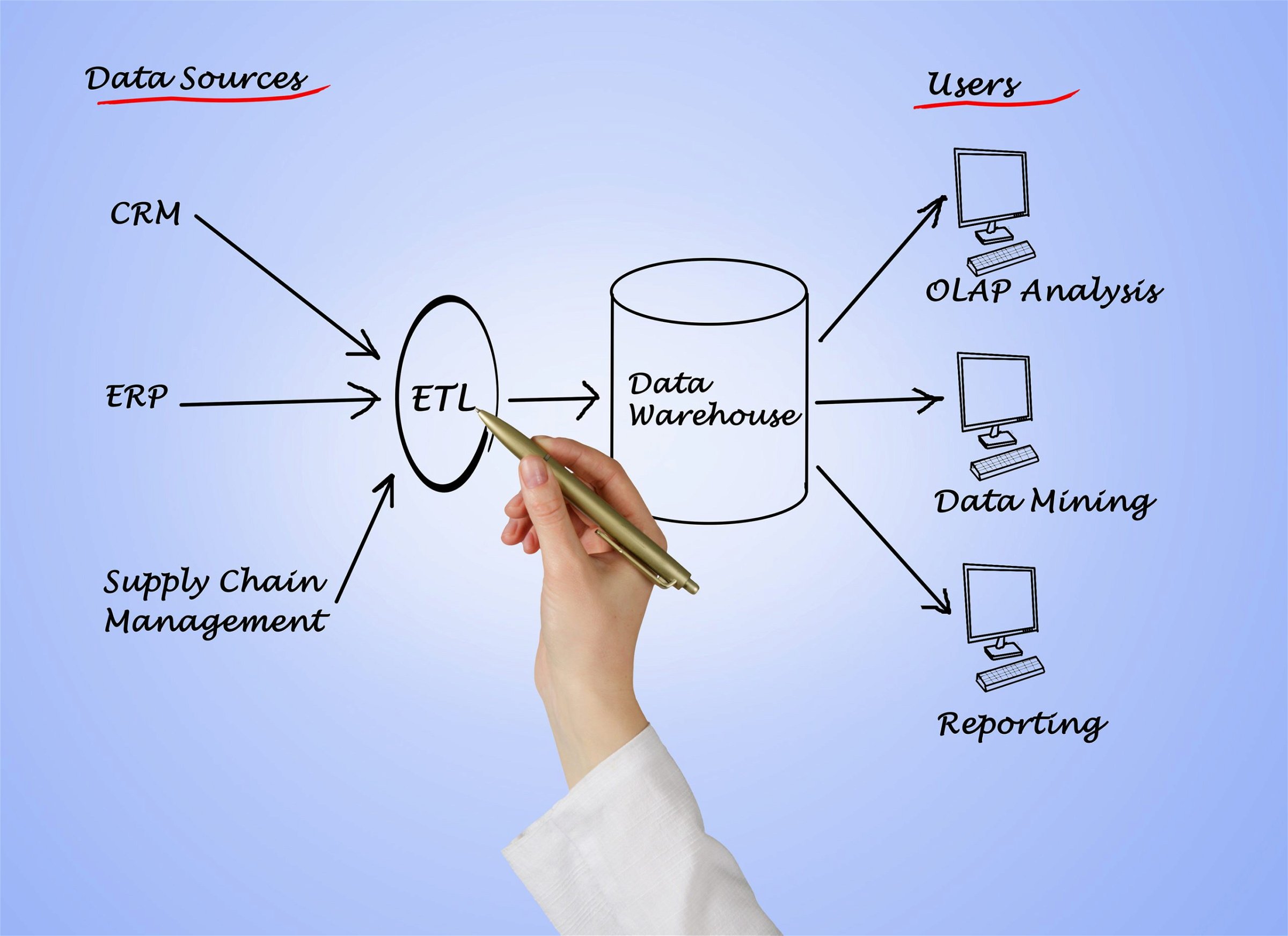

- Staying safe from the unexpected requires intelligent use of multiple data sources, new, traditional, structured or not, of diverse typology, even in natural language, and easy to find or obscure to the provider. And all of them must be leveraged by certification in supply chain management.

- You need expert staff and precisely the links in the supply chain have long suffered thinning plans that have reduced their workforce like never before. And when older veterans leave the organization, they will carry with them a lot of knowledge and experiences that have been treasured for decades, with the consequent brake on exhaustive analyzes that require intelligence to interpret the information.

- Designing a supply chain network with full intelligence is capable of managing in real-time large amounts of structured and unstructured data from internal and external sources, including data sets that may previously have been difficult to reach. Precisely anticipating future demand and managing assets, inventory, and shipments in real-time improve the bottom line for any operator, requiring an optimized, near-automatic supply model.

The new forms of commerce that have fostered the Internet, the cloud or connected objects will only gain shape if they have the most efficient logistics processes, a modern supply chain that meets their high demands with a permanent journey to excellence. Professional certification in supply chain management offered by Imarticus can lead to a truly digital supply chain.

Efficient Collaboration: To swiftly and effectively deal with issues when they arise, it is vital to maintain a smoother flow of information across the supply chain to avoid any miscommunications and confusion.

Efficient Collaboration: To swiftly and effectively deal with issues when they arise, it is vital to maintain a smoother flow of information across the supply chain to avoid any miscommunications and confusion. Supply chain certification enables professionals to make data-driven decisions at strategic, operational, and tactical levels. In the Supply Chain Management field, there is a shortage of professionals with process and analytics talents. This certification prepares you for high-demand job roles such as Demand Planner, Data Scientist, Supply Planner, and Supply and Operations Planner.

Supply chain certification enables professionals to make data-driven decisions at strategic, operational, and tactical levels. In the Supply Chain Management field, there is a shortage of professionals with process and analytics talents. This certification prepares you for high-demand job roles such as Demand Planner, Data Scientist, Supply Planner, and Supply and Operations Planner.