Logistic regression and linear regression are two integral algorithms of machine learning. These two are supervised learning methods that are used for making forecasts and predictions.

Although both regression techniques are used for the purpose of machine learning, they still have a lot of differences in the way they are used. A good data analytics course with placement can help one understand the distinctions in a simple way. When talking about logistic regression vs linear regression, we need to understand that logistic regression is mainly used to solve classification problems, whereas linear regression is used to solve regression problems.

Read on to learn more about logistic regression vs linear regression – the regression techniques of machine learning.

Logistic Regression

Logistic regression is one of the most used machine learning algorithms. It is a supervised technique that is generally used for classification problems but can also be used for regression problems. It uses simple independent variables to make predictions on categorical and dependent ones.

Logistic regression works well with Python programming, which requires minimal coding and does the job of solving classification problems. the output of this technique ranges between 0 to 1. It is based on the institution of maximum likelihood estimate, which means observing data should be the most obvious.

Linear Regression

Linear regression is an old and simple form of a machine learning algorithm. It is a supervised technique that is specifically used for solving regression problems. This technique uses independent variables to make predictions on the continuous dependent variables. It is also compatible with Python programming, much like its counterpart.

As the name suggests, a linear regression graph is always in the form of a straight line, and the main objective is to find the best-fit line for accurately denoting the variables. If only one independent variable is used, then it is called a simple linear regression, and if more than one independent variable is employed, then it is known as multiple linear regression.

Logistic Regression vs Linear Regression – The Differences

Both regression techniques are widely used for machine learning, yet each one addresses particular problems. However, both can be used for data visualisation, and there are certain tasks that each performs separately. The key differences in logistic regression vs linear regression can be explained as follows:

Type of variable and output

Logistic regression is predominantly used to specifically predict and deal with the categorically dependent variables. A particular set of independent factors is associated with this regression technique. This technique is mostly based on probabilities.

On the other hand, linear regression uses only continuous dependent variables based on a particular set of independent variables. These independent variables take numeric values and reference from staying in any category or group.

Degree of complexity

Logistic regression has a more complex structure of equations, that makes it challenging to interpret and understand this model.

Whereas linear regression is a simple model and involves a comparatively simple structure of equations. It is easily understandable and interpreted.

Application and scope

Logistic regression is mainly applied to solving classification problems. It can, however, solve some regression problems as well. It is slightly wider in scope.

On the other hand, linear regression is only applied to solving regression problems. It cannot solve classification problems. Hence, it is comparatively narrow in scope.

Type of graphical representation

In logistic regression, the graph forms an S-shaped curve. Thus, the type of graph is S-shaped. It can be easily used for classifying samples.

In contrast, the graph of linear regression is a straight-line curve. It focuses on finding the proper fit line for precisely predicting the output.

Method used

Logistic regression uses the maximum likelihood estimation method. In this method, the coefficients of the regression method are chosen to maximise the probability of the variables until the iteration processes are complete.

On the contrary, linear regression uses the ordinary least square estimation method. In this method, the coefficients of the recreation method are chosen to lower the sum of the squared variables to find the best-fit line.

Mathematical equation

The mathematical equation used in logistic regression is:

y(x) = e(a0 + a1x1 + a2x2 + … + aixi) / (1 + e(a0 + a1x1 + a2x2 + … + aixi))

On the other hand, the mathematical equation used in linear regression is:

y = a0 + a1x1 + a2x2 + … + aixi

Where,

y stands for the response variable

xi stands for the predictor variable

ai stands for the average effect on y as xi increases by one (when all other predictors are fixed)

Type of output

Logistic regression must always have a categorical or numeric output that ranges between 0 to 1 or is present in the form of a clear yes or no answer, and so on.

On the other hand, the output of linear regression must always be in the form of a continuous value. For instance price, weight, age, and so on.

Correlation between independent variables

In the case of logistic regression, there exists no correlation between the independent variables.

On the contrary, in the case of linear regression, there may or may not exist a correlation between the independent variables.

The Better Approach to Machine Learning

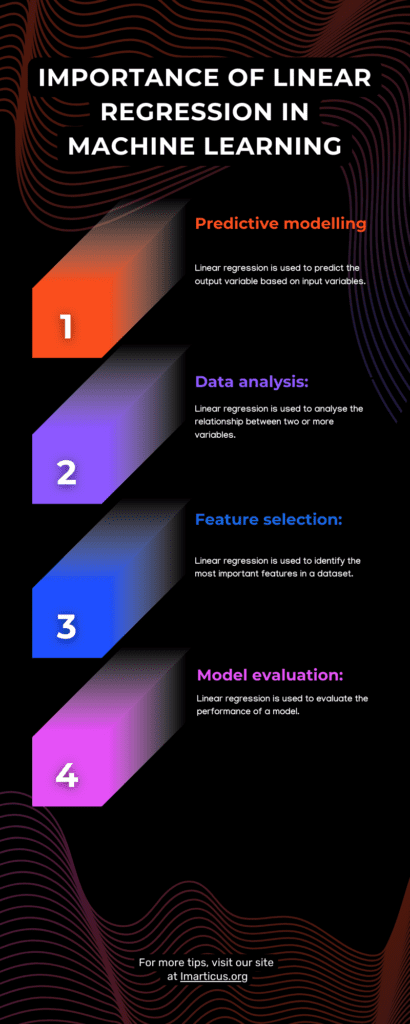

This is another debatable topic for many specialists. When it comes to supervised Machine Learning then linear regression is considered to be the best-suited approach. Linear regression is best suited for predicting continuous outcomes.

For instance, linear regression can be used for predicting the weight of an individual if his height is known.

The equation appears as follows:

Weight = 70 + 2 x (60) = 190 lbs

Where height= 60 inches

Here, the effect of one independent variable on the outcome is analysed.

However, when unsupervised or semi-supervised Machine Learning is considered then logistic regression is the most suitable approach. It works best with assumptive data and refrains from using a rigid approach. Logistic regression is best suited for producing a discrete value.

For instance, logistic regression can be used for predicting whether a student will be able to crack a competitive examination or not. Whether a political candidate will win the election in an area or not. This approach presents binary outcomes where it has only two straightforward alternatives.

Conclusion

Regression is an essential Machine Learning tool that makes predictions and creates relationships among variables. Machine learning experts are in demand in every organisation nowadays. If you are looking to gain professional knowledge about regression approaches and learn what is logistic regression vs linear regression then a data analytics course with placement can help you to get a good piece of work. Sign up for the Postgraduate Program In Data Science And Analytics by Imarticus and kickstart your career in data science.